The basic concept of the eation intelligent hanging production line system is to hang the entire piece of clothing on a hanger, and automatically send it to the next process operator according to the pre-entered process sections, greatly reducing handling, binding, and folding. Waiting for non-productive time. When the production employee completes a process, he only needs to press the control button, and the hanging system will automatically transfer the hangers to the next process station.

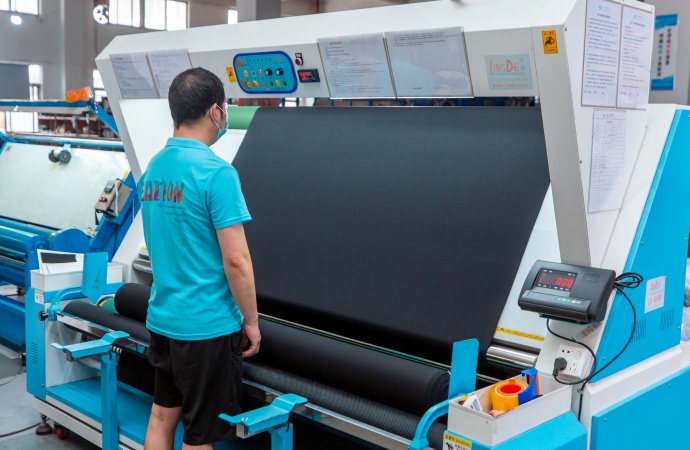

Sportswear Factory A

This production facility is located in Guangdong, China. With its complete industrial chain, efficient production capacity and superior geographical location, Guangdong has a strong competitiveness in the global market

The factory covers an area of 10,000 square meters and has a total of 300 workers.

Our Intelligent Hanging System has significantly reduced wait and idle times in production through automated material transfer., This reduces the overall cycle time from production to delivery by 30%