The 10 Unspoken Secrets of Hoodie Manufacturers: A Guide for Hoodie Brands

As the brand of sweatshirts, have you ever encountered these frustrating problems: The sweatshirts ordered in bulk have large areas of pilling, which affects the brand's reputation; The cooperation factory delays the delivery date, missing the sales peak season; The second batch of sweatshirts of the same style have significantly lower quality...

In B2B cooperation, the "hidden operations" of manufacturers often determine the competitiveness of your products. This article is specifically designed for brands to dissect the 10 key secrets of hoodie manufacturing, helping you avoid cooperation pitfalls and find production partners that can achieve long-term mutual benefit.

1."The 'cost trap' in fabric procurement"

Don't be deceived by the label "100% cotton" - even though both are made of cotton, the purchase price of long-staple cotton is 1.8 times that of ordinary fine cotton, and the balling rate of the sweaters made from them differs by 40%. A fast-fashion brand once tried to cut costs by having the factory replace the long-staple cotton stipulated in the contract with blended cotton. As a result, after receiving 5,000 orders, customers complained that the clothes "looked like old ones after washing 3 times", and eventually had to recall all the products in full.

Suggestions for the brand: Clearly indicate the fabric grade in the purchase contract (for example, for long-staple cotton, the fiber length should be ≥ 38mm), and require the factory to provide a third-party inspection report. During the first collaboration, randomly select at least 3% of the fabric samples for testing to avoid passing off inferior products as good ones.

2."Exclusive assets" of the pattern data

Professional factories will establish exclusive size database for the cooperating brands. When an outdoor brand collaborates with the factory, it requires adjusting the shoulder width (2 cm narrower than the European version) and lengthening the sleeves (3 cm longer than the standard version) according to the body shape of Asian men. This set of size data becomes the core competitiveness of the brand - consumer feedback states, "Other brands' sweatshirts always don't fit well. Only your brand is like tailor-made."

Unprofessional factories would simply use a generic design to cater to all customers. Once, a new brand encountered an embarrassing situation: for the same size of sweatshirt, a 175cm customer felt it was too big, while a 180cm customer felt it was too small.

Key points of cooperation: The factory is required to provide a "fashion measurement test report", which should include data from at least 50 different body types for wearing tests; The ownership of the fashion measurement data is agreed upon to prevent the factory from sharing your exclusive fashion designs with competitors.

3. "Cost Balancing Technique" for Sewing Processes

The process of reinforcing the neckline is the most prone to substandard work. According to the standard procedure, it should use "three needles + hemming" (12 needles per inch), which costs 15% more than the ordinary single-thread sewing. However, it can ensure that the neckline remains intact after 50 washes. A certain trendy brand once overlooked this point. As a result, the cooperating factory used single-thread sewing, leading to a complaint rate of 30% for the 2,000 pieces of sweatshirts after they were launched on the market.

Acceptance criteria: Develop a "Process Checklist", clearly defining the sewing requirements for key areas (such as the cuffs must be double-stitched and the side seams need to be bound), and store the process sample garments before the mass production to serve as the acceptance basis.

4."Batch Risk" in the dyeing process

For the same color series of sweatshirts, color differences between two batches of orders are a common dispute in B2B cooperation. A sports brand customized theme sweatshirts for the World Cup. The first batch was bright red, while the second batch was slightly orange-red. This led to the inability to uniformly put them on the shelves. Upon further investigation, it was found that the factory, in order to meet the production schedule, entrusted the two batches of fabrics to different dyeing factories for processing without conducting a color fastness comparison.

Risk Control: The factory is required to implement "cylinder number management". Orders of the same batch must be produced by the same dyeing factory and the same dyeing cylinder; provide a "color difference report" (the ΔE value should be ≤ 1.5, which is almost invisible to the naked eye), and reserve 3% of spare parts to maintain color consistency when making up orders.

5. The "hidden weaknesses" in the printing supply chain

When you request for high-level gradient printing, small factories may outsource it to a third-party printing factory. This will lead to three problems: the delivery time is uncontrollable, the quality is difficult to trace, and the cost increases (the factory will charge an additional 20% of the intermediate fee). A designer brand once had a disaster because the outsourced printing had large areas of cracking, but they blamed the factory and said, "It's the problem of the printing factory."

Cooperation inspection: Before signing the contract, verify whether the factory has its own printing workshop. Request a visit to the production site. In the contract, specify "Outsourcing activities without the consent of the brand owner are prohibited", and agree on the relevant liability for breach of contract.

6."Additional Costs" in the quotation sheet

The "XX $ / piece" listed on the factory quotation usually does not include these hidden charges: urgent delivery fee (an additional 30% charge for delivery within 3 days), small batch premium (the unit price increases by 15% for orders under 500 pieces), and redesign fee (an additional $300 is charged for each design modification). A newly established brand once failed to understand the quotation terms, and the final settlement price for a 500-piece order was 40% higher than the quoted price.

Safety tips: Request the factory to provide a "total package price" quotation, clearly listing all the costs corresponding to the minimum order quantity, the number of revisions, and the delivery cycle; agree on a "quotation validity period" (suggesting 30 days) to avoid cost out of control due to raw material price increases.

7 .The "Life-and-Death Race" of Supply Chain Response

During peak seasons, the factory's order processing capacity determines your replenishment efficiency. a certain e-commerce brand needed to replenish 3,000 pieces of best-selling sweatshirts within 7 days. The cooperating factory successfully delivered the goods through a "flexible production line" (reserving 20% of its capacity to handle urgent orders), while its competitors, due to the factory's schedule being fully booked, missed the sales peak and suffered losses of over Three hundred thousand dollars.

Cooperative Inspection: During the on-site inspection, the focus should be on the "emergency production capacity" of the factory - does it have backup production lines? Can it coordinate with fabric suppliers to prioritize supply? It would be best to stipulate in the contract the "urgent order response time" (such as confirming the schedule within 48 hours).

8. The "technical bottlenecks" for the implementation of the design

Your designer drew a hoodie with "hidden side pockets + hooded drawstring that conceals the earphone hole". However, the factory said "can't do it"? This might not be a design issue, but rather the factory's technical limitations. A capable factory would have a "process engineer" who can convert the design drawings into a feasible production plan. A luxury brand once requested a "seamless bonded hoodie", and a professional factory achieved the design concept through ultrasonic bonding technology, with the product's price increasing by 300%.

Selection criteria: The factory is required to provide a "special process case library", including actual application cases of technologies such as seamless joining, laser cutting, and 3D printing; during the first cooperation, 50 sample garments will be produced for trial production to verify the factory's ability to implement the design.

9. Inventory Sharing "Cost Reduction Plan"

Smart factories will share inventory data with their key customers. A certain chain brand integrated its ERP system with the factory to monitor fabric inventory and the progress of ongoing orders in real time. When it was detected that the inventory of a certain hoodie was below the safety level, the system automatically triggered a replenishment alert, shortening the preparation period from 15 days to 7 days and increasing the inventory turnover rate by 50%.

While traditional factories operate in a "black box" manner, you never know if the raw materials are sufficient. Usually, problems are only discovered when the products run out of stock.

Deep cooperation suggestion: Negotiate with the main factory on the "joint purchasing" model - you pay 30% of the fabric price in advance, and the factory reserves common fabrics in advance, significantly shortening the production cycle.

10.The "bottom-line guarantee" of quality traceability

Professional factories will assign a unique traceability code to each piece of sweatshirt, recording information such as the fabric batch, the sewing workers, and the quality inspectors. When a quality issue occurs with a certain batch of sweatshirts, it can quickly pinpoint the specific link (such as "The 12th group of workers had a low qualified rate for the cuffs"). A school uniform brand once used this system to reduce the handling time of customer complaints from 7 days to 24 hours.

Essential terms for cooperation: Require the factory to establish a "quality traceability system" and provide the "quality inspection report" (including the test results of the AQL2.5 sampling standard); Agree on the "quality issue compensation standard" (such as if there are batch non-conformities, compensation shall be made at 1.5 times the order amount).

Final Note: The essence of B2B cooperation is "risk sharing and benefit sharing". As the brand owner, what you need is not "the factory with the lowest quote", but "a production partner who can help solve your problems".

Conclusion

Next time when you visit the factory, don't just look at the sample clothes in the exhibition hall. Ask more questions like these: "How do you handle the cases where the fabric is not up to standard?" "How much does it cost to make adjustments to the pattern?" "How much production capacity can you guarantee during peak seasons?" - The answers to these questions often reveal the truth better than the quotation list.

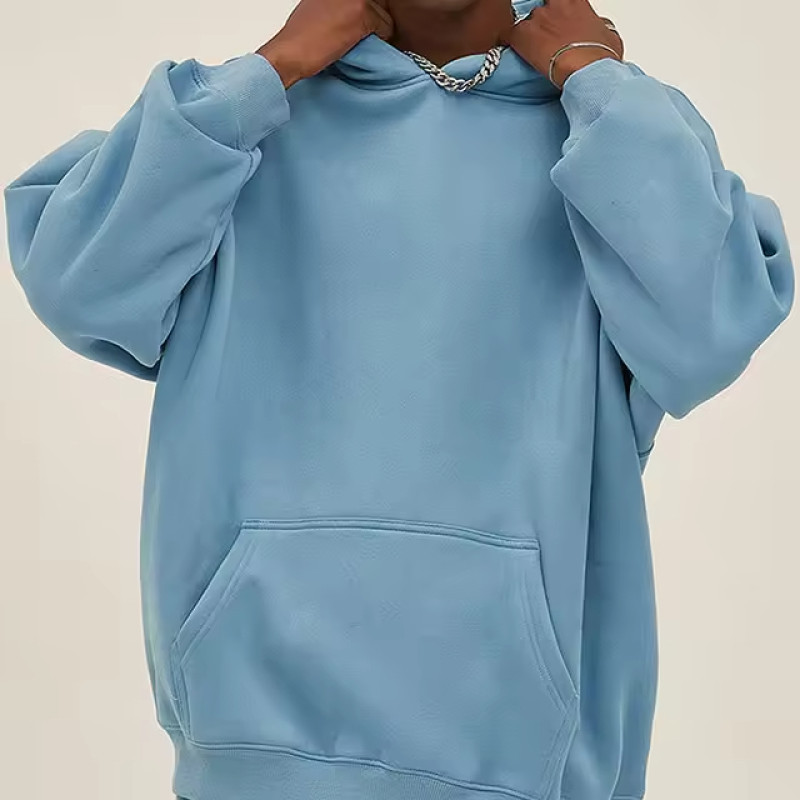

A Leading Provider of Streetwear Hoodies

Features a classic crewneck collar that offers a versatile and timeless look, making it easy to style with various outfits.

Made from high-quality, thick cotton fleece, ensuring exceptional warmth and softness. This material is perfect for cold weather, providing insulation and comfort.

Features a full-length zipper for easy wear and removal. The durable and smooth zipper ensures hassle-free use and a secure fit.